Table Of Content

Hire certified HVAC contractors for duct installation and repairs. Because the layout of most ductwork systems fit into the “normal” range, and our calculator factors for that already. Getting these data right means you’ll get the ductwork size right. This is vitally important, something we’ll belabor a bit, because ducts that are too small or narrow will wreck efficiency and make the system work too hard, leading to early mechanical failure.

Should HVAC Return Duct Be the Same Size?

Attic duct insulation improves energy efficiency in unconditioned attics and prevents AC units from overworking. Replacing ductwork in an attic costs $2,200 to $5,600 on average, depending on the accessibility and system size. New ductwork installation costs $2,400 to $6,600 on average to retrofit an existing home without ducts.

How Return Air Vents Contribute to Energy Efficiency

Density of 120°C air is 0.898 kg/m3; ambient air is 1.204 kg/m3. For Figures 5A and 5C, calculate the thermal gravity effect and fan total pressure required when the air is cooled to −34°C. The heat exchanger and ductwork (section 1 to 2) total pressure losses are 170 and 70 Pa respectively. The density of −34°C air is 1.477 kg/m3; ambient air is 1.204 kg/m3.

Types of Duct Insulations (with Specifications)

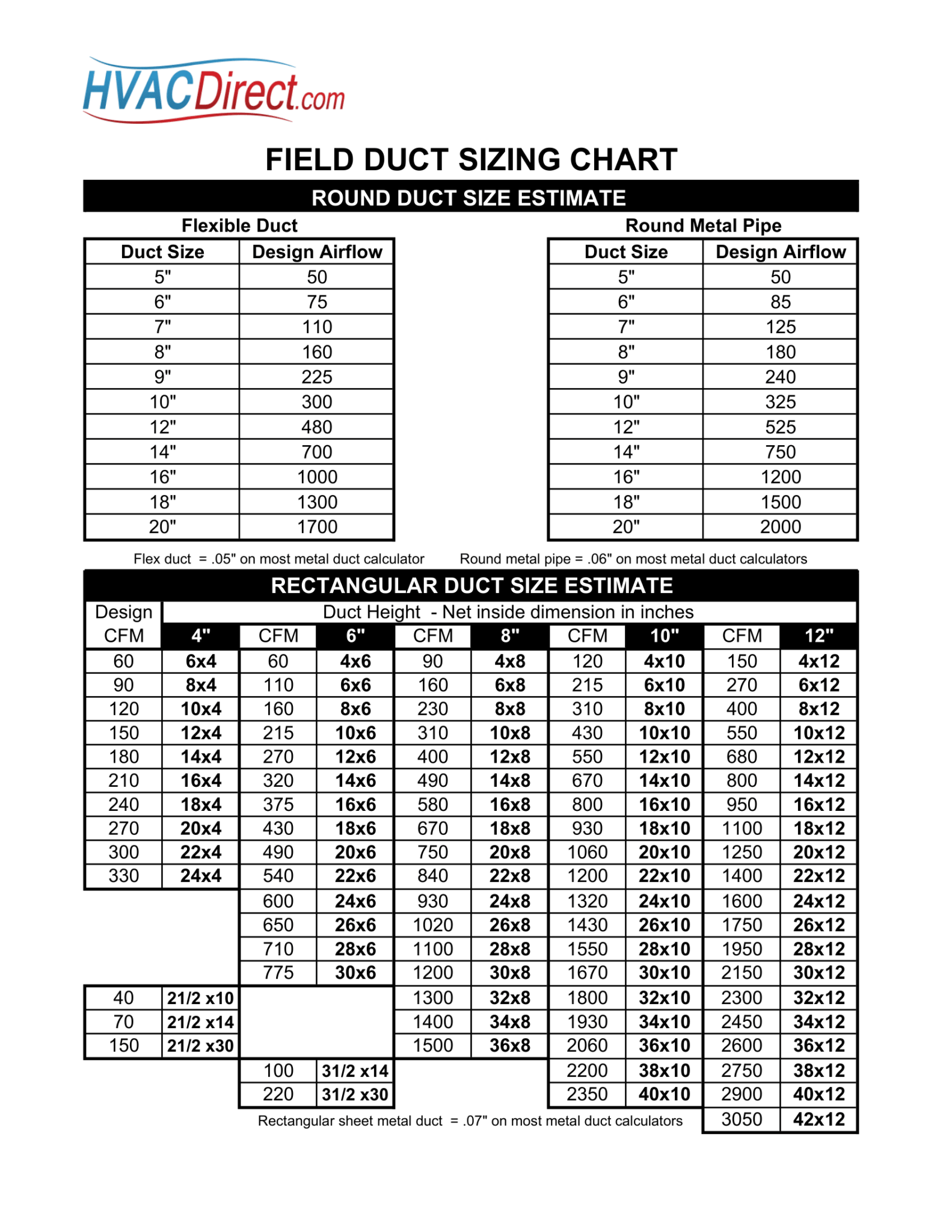

The airflow difference between points 2 and 4 represents the deficiency in airflow from design airflow. Compare the total pressure resistance of 250 mm, 1.8 m installed length, galvanized steel spiral and flexible duct, 0% compressed (fully stretched), 4%, 15%, and 30% compressed. Airflow is 470 L/s, air density is 1.204 kg/m3, and absolute roughnesses ε of spiral round and flexible ducts are 0.12 mm and 0.9 mm. Calculate using the ASHRAE Duct Fitting Database [DFDB; ASHRAE (2016)]. Furthermore, without a return air duct in each major room, the supply duct air has to "push" all of the air in the room out of the way as it makes its way towards you. The return air ducts help pull the air as it is being pushed.

If a given duct diameter produces a velocity above 1500 FPM, then using ductwork with larger diameter is another way to offset it. Chapter 45 of the 2019 ASHRAE Handbook—HVAC Applications discusses proper design of exhaust stacks and placement of air intakes to avoid adverse air quality impacts. Experience provides some general guidelines on air intake placement. Unless dispersion modeling analysis is conducted, air intakes should never be located on the roof in the same architectural screen enclosure as exhaust outlets. If exhaust is discharged from several locations on the roof, intakes should be located to minimize contamination. Architectural screens placed around rooftop equipment to reduce noise or hide equipment interact with the windflow patterns on the roof and can adversely affect exhaust dilution.

The last column is the number of round rigid duct you need. The size of return air ducts is an important component, as they must be big enough to transport air back to the HVAC unit. If the return air ducts are too small or narrow, your airflow will be restricted, and it’ll be harder to get the building to your desired temperature. For more information, check out my article on how to fix HVAC airflow. All ductwork and plenum transverse joints, longitudinal seams, and duct penetrations should be sealed.

Fire safety codes often refer to the testing and labeling practices of nationally recognized laboratories, such as Factory Mutual and Underwriters Laboratories (UL). UL’s annual Building Materials Directory lists fire and smoke dampers that have been tested and meet the requirements of UL Standards 555 and 555S. This directory also summarizes maximum allowable sizes for individual dampers and assemblies of these dampers. Smoke dampers are classified by (1) temperature degradation [ambient air or high temperature (120°C minimum)] and (2) leakage at 250 and 1000 Pa pressure difference (2 and 3 kPa classification optional). Smoke dampers are tested under conditions of maximum airflow. UL’s annual Fire Resistance Directory lists fire resistances of floor/roof and ceiling assemblies with and without ceiling fire dampers.

Can Round Flexible Duct Be Used for HVAC Return Air?

There are 3 blue lines at 600 cfm, representing 3 possible duct sizes as indicated by the 3 green lines which corresponds to 16″, 14″ and 12″ respectively. If you don’t mind a little engineering work, then you can make a better decision by using the duct sizing friction loss chart. I limit the duct size to 14″ because that’s what you normally can get from online stores and Home Depot. If you appoint a contractor, they should be able to get you something bigger than 14″. Air conditioning ducts are sized based on how much airflow your HVAC unit has.

Design the Supply and Return Grille Location

Our third-party vendor uses a national criminal database ("NCD") to screen service professionals. Business owners or principals with felony arrests that carry a pending decision or who are convicted of felonies in the past 7 years ago will not be admitted to the network. If you choose to hire this pro for your project, you'll agree on final pricing before any work begins - and you'll never pay before it's done.

Church Saves $100000 on HVAC Ventilation Metal Duct Replacement - ACHR NEWS

Church Saves $100000 on HVAC Ventilation Metal Duct Replacement.

Posted: Wed, 24 Nov 2021 08:00:00 GMT [source]

Inlet spin can be avoided by providing an adequate length of duct between the elbow and the fan inlet, as shown by Figure 16. Two L/Do duct lengths upstream of the fan inlet reduces swirl and pressure loss (loss coefficient) by approximately 45% (Table 7). For rated performance, air must enter the fan uniformly over the inlet area in an axial direction without prerotation. Nonuniform flow into the inlet is the most common cause of reduced fan performance. Such inlet conditions are not equivalent to a simple increase in system resistance; therefore, they cannot be treated as a percentage decrease in the flow and pressure from the fan. A poor inlet condition results in an entirely new fan performance.

Centrifugal fans should not abruptly discharge to the atmosphere. A diffuser design should be selected from Fitting SR7-2 or SR7-3. Consult the SR7-series fittings of the ASHRAE Duct Fitting Database (ASHRAE 2016) for guidance in the design of fan/ductwork connections. Huebscher (1948) developed the relationship between rectangular and round ducts that is used to determine size equivalency based on equal flow, resistance, and length.

If it is not, the outdoor unit will struggle to keep your house cool. Make him/her prove to you that the interior coil will handle the outside unit. On an older existing home that is being retrofitted for central air-conditioning, they are a must. Sometimes, you can use a kitchen pantry closet or a hall closet. We have often been able to put a duct in one corner of the pantry or closet. This duct extends up to the second floor where it often lines up with an interior hallway wall.

Flex ducts always need insulation in unconditioned crawl spaces, and they should hang above the ground. Especially in humid climates, rigid metal ducts last longer in unconditioned crawl spaces. Ductwork lasts 10 to 20 years on average before it needs replacing. Most ducts need work when upgrading to bigger or higher-efficiency units. Contractors advise cleaning the air ducts every 3 to 7 years, or with duct repairs.

No comments:

Post a Comment